The Pros and Cons of Silicone vs. Aluminum Intake Systems in the Automotive Tuning Industry

When it comes to automotive tuning and performance upgrades, one of the key components often discussed is the intake system. The intake system plays a significant role in the vehicle’s engine efficiency and overall performance, as it is responsible for directing air into the engine. For enthusiasts looking to enhance their cars’ intake systems, two popular materials used for intake tubes are silicone and aluminum. Both materials have their advantages and drawbacks, which can influence the decision-making process depending on the vehicle's needs, purpose, and budget.

In this blog, we’ll explore the pros and cons of both silicone intake systems and aluminum intake systems to help you make an informed decision for your car modification project.

Silicone Intake Systems

Pros:

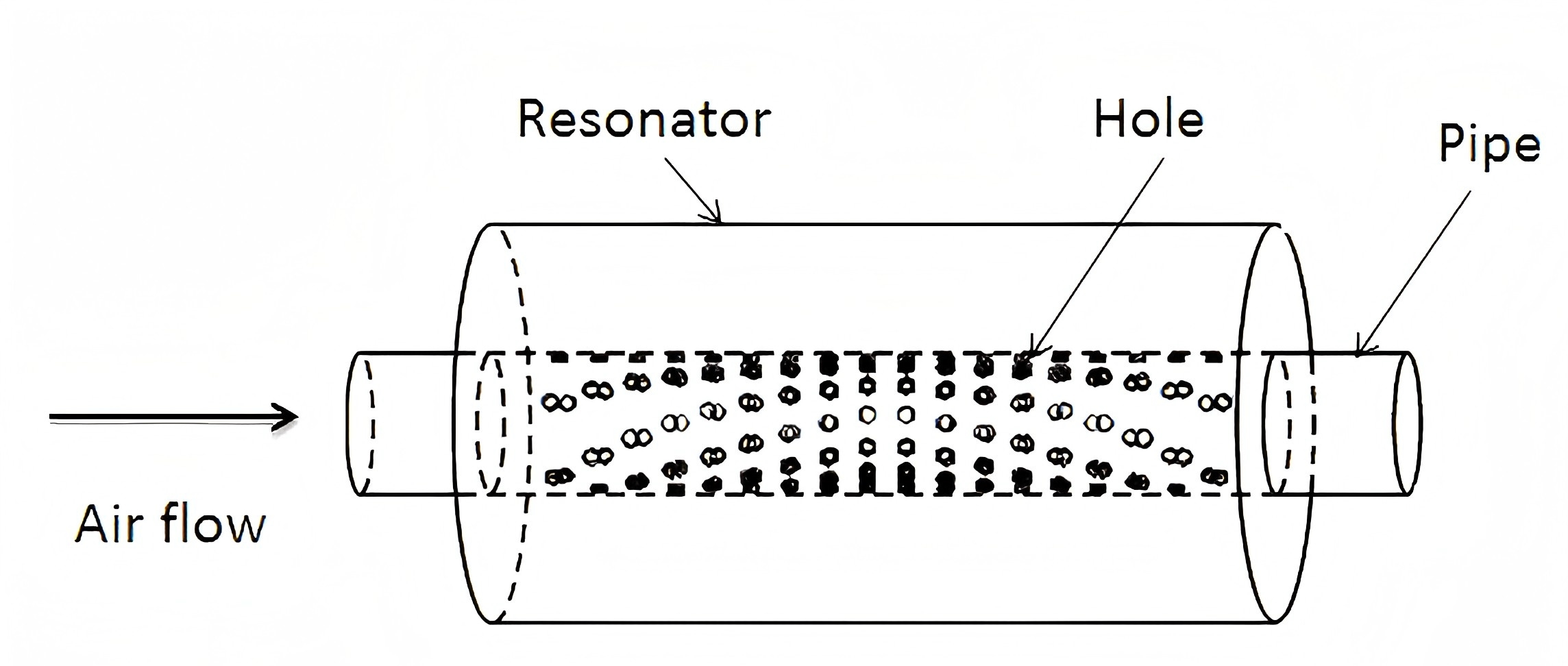

1. Flexibility and Customization:Silicone hoses are highly flexible, which makes them ideal for custom intake designs. They can be bent easily without kinking, which allows for more freedom in routing the intake system. This is especially useful for tight spaces or custom builds where precision is key.

2. Durability Under High Temperatures:Silicone can withstand high temperatures without degrading, making it a suitable choice for performance vehicles, especially those that undergo heavy use, such as racing cars. They are resistant to high levels of heat from the engine and exhaust, ensuring long-lasting performance.

3. Lightweight:Compared to metal tubing, silicone hoses are incredibly lightweight. This can help reduce the overall weight of the vehicle, which is crucial for performance-focused builds where every gram counts.

4. Resistance to Corrosion:Silicone is highly resistant to corrosion and oxidation. This means that even in humid or salty environments, silicone hoses will not rust or degrade, which can be a concern with metal-based intake systems.

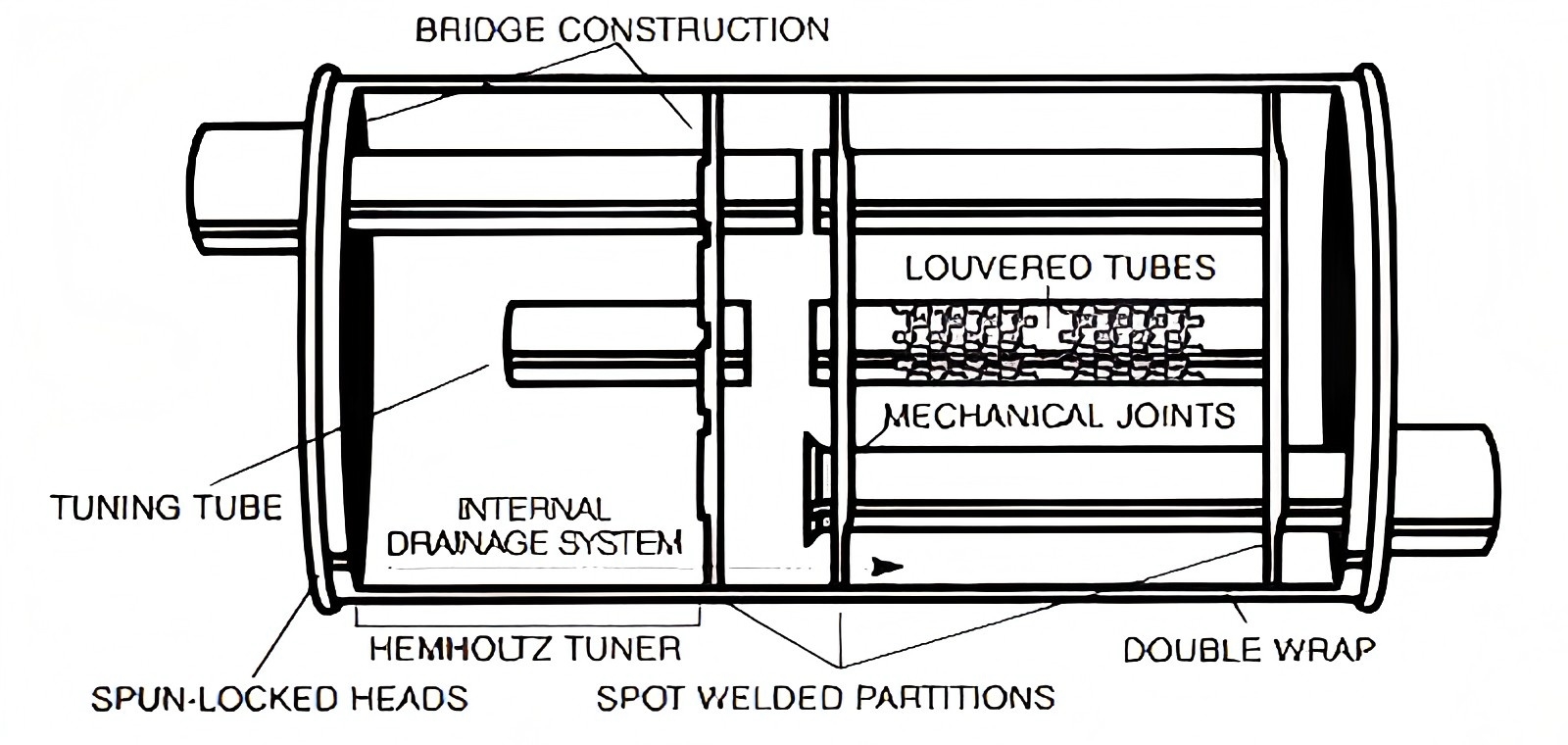

5. Noise Reduction:Silicone has natural vibration-dampening properties. This can result in a quieter and more refined intake sound compared to the harsher, metallic noise generated by aluminum tubes.

Cons:

1. Less Aesthetic Appeal:While silicone hoses come in various colors, they might not match the aesthetic appeal of some enthusiasts who prefer a more polished, high-end look. Aluminum systems often provide a sleeker, more professional finish.

2. Limited Resistance to Oil and Fuel:Silicone can degrade when exposed to certain oils, fuels, or chemical additives, especially in high-performance engines where these substances might be present. In some cases, prolonged exposure to these elements could lead to cracking or breakdown.

3. Prone to Heat Expansion:Although silicone can withstand high temperatures, it is still susceptible to heat expansion. This could lead to the hose expanding slightly under extreme conditions, which could affect performance or cause a poor seal if not properly installed.

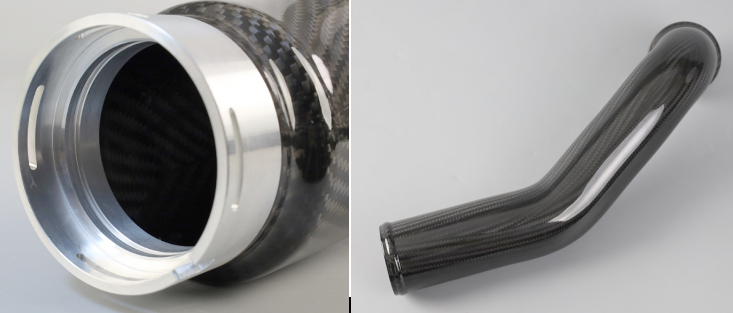

Aluminum Intake Systems

1. Pros:Aesthetic Appeal:Aluminum intake tubes offer a sleek, shiny finish that is often favored for its clean and polished look. For many car enthusiasts, this polished appearance adds to the overall "wow factor" under the hood.

2. Strength and Durability:Aluminum is a strong material that is highly resistant to physical damage. It doesn’t crack or tear as easily as silicone, making it a robust option for high-performance applications that experience a lot of stress or extreme driving conditions.

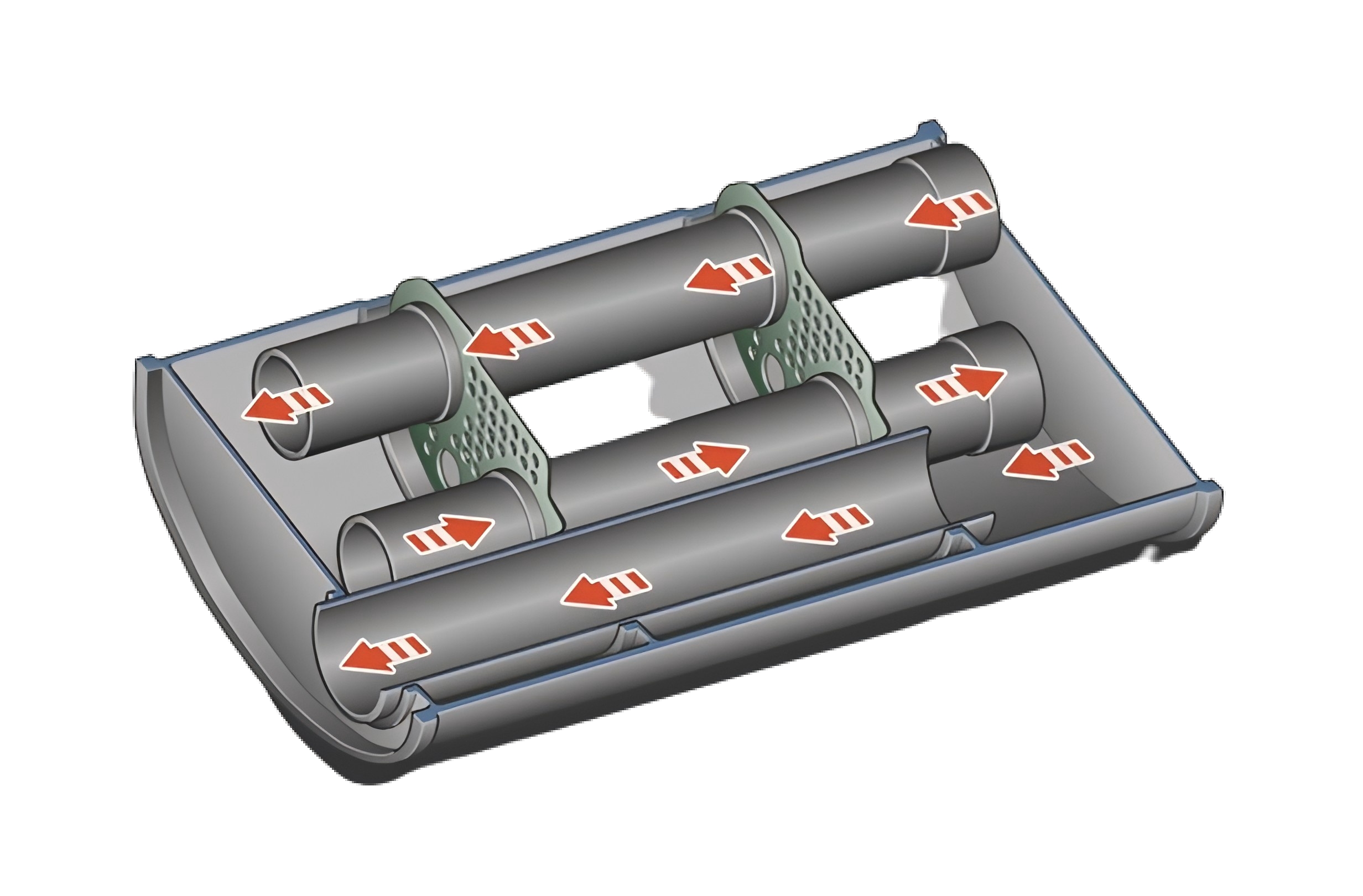

3. Temperature Control:Aluminum has excellent thermal conductivity, meaning it can help dissipate heat more effectively than silicone. This can result in cooler intake temperatures, potentially improving engine performance, especially in forced induction setups like turbocharged or supercharged vehicles.

4. Low Maintenance:Aluminum is not susceptible to wear and tear in the same way as silicone. It is resistant to many chemicals, including oils and fuels, making it a more durable choice in environments where such fluids are present.

5. Precision Fitment:Because aluminum intake tubes are often fabricated from metal, they can be precisely manufactured for a perfect fit. This precision often results in a more rigid and stable intake system that holds its form over time.

Cons:

1. Heavier Than Silicone:Aluminum is significantly heavier than silicone, which can be a concern for those who are looking to reduce the overall weight of their vehicle. While the difference may not be massive, it could be significant for track or race cars where every bit of weight counts.

2. More Expensive:Aluminum intake systems are generally more expensive than silicone alternatives. The cost is attributed to the manufacturing process and the materials themselves. For budget-conscious enthusiasts, this can be a deterrent.

3. Risk of Cracking or Denting:While aluminum is durable, it is also prone to denting and cracking under extreme force or impact. This could be a concern for vehicles that are regularly exposed to harsh environments or off-road conditions.

4. Limited Flexibility:Unlike silicone, aluminum intake tubes are rigid and cannot be easily bent. This means that customization of the intake routing might be limited, especially in confined spaces. Additionally, an improper fit could result in leaks or poor airflow.

1.

Which Should You Choose?

Both silicone and aluminum intake systems have their merits, and the best choice will depend on your car’s needs, your budget, and the specific goals of your performance upgrade.

l Choose Silicone if:

1. You need a flexible, lightweight, and cost-effective solution.

2. You’re working on a custom build where routing and fitment are crucial.

3. You prioritize ease of installation and noise reduction.

4. Your car operates in a relatively clean environment (not exposed to too many oils or chemicals).

l Choose Aluminum if:

1. You’re looking for a more polished, professional appearance.

2. Your focus is on durability, strength, and resistance to impact.

3. You want superior heat dissipation and temperature control for high-performance applications.

4. Your car is exposed to harsh conditions and you need an intake that is low-maintenance and resistant to damage.

o

In the end, both materials can enhance the performance and aesthetic of your intake system, but understanding their unique properties will ensure you make the best choice for your vehicle.

Have you upgraded your intake system yet? Which material did you choose, and why? Let us know your thoughts in the comments below!