The Pros and Cons of Carbon Fiber Intake Systems in Car Modifications

In the world of automotive performance upgrades, carbon fiber intake systems have become increasingly popular among car enthusiasts and tuners. These high-tech components not only enhance a vehicle’s aesthetic appeal but also promise performance benefits. However, like any modification, they come with their own set of pros and cons. In this blog, we’ll explore the advantages and disadvantages of upgrading to a carbon fiber intake system in the car tuning world.

Pros of Carbon Fiber Intake Systems

1. Lightweight Design

Carbon fiber is renowned for being incredibly strong yet extremely lightweight. Swapping out a stock plastic or metal intake for a carbon fiber one can slightly reduce the vehicle’s overall weight—especially important for high-performance and track-focused builds where every gram counts.

2. Improved Heat Resistance

Carbon fiber has excellent thermal insulating properties compared to metal. This means it absorbs and retains less heat from the engine bay, allowing cooler air to flow into the engine. Cooler air is denser, leading to better combustion and potentially increased horsepower and torque.

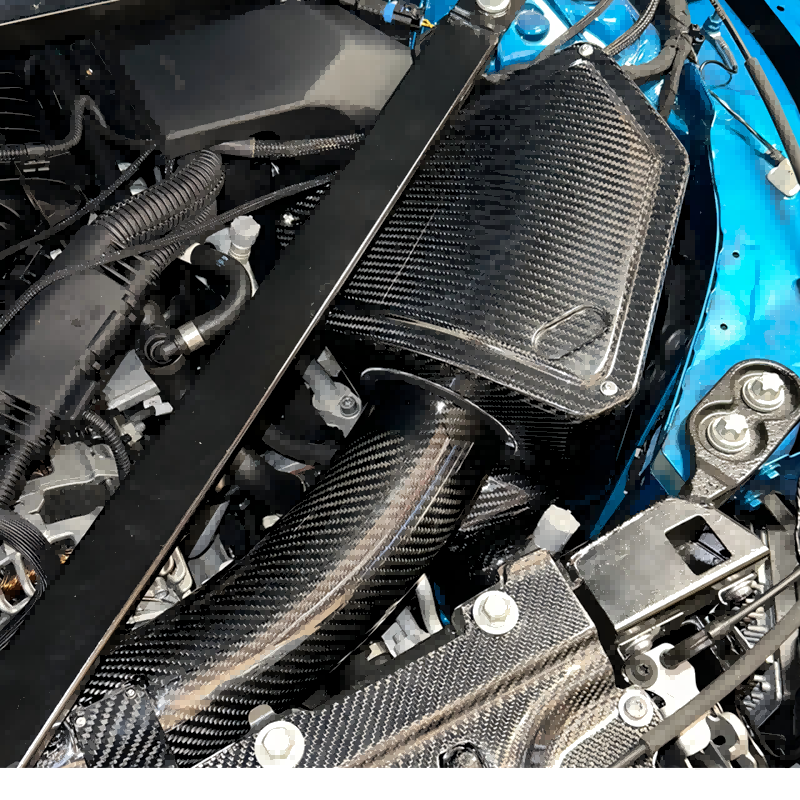

3. Aesthetic Appeal

There’s no denying the visual impact of carbon fiber. A well-crafted carbon fiber intake system adds a premium, high-performance look to any engine bay. For many enthusiasts, this is as important as the functional improvements.

4. Enhanced Airflow

Most aftermarket carbon fiber intakes are designed with performance in mind. They often feature smoother internal surfaces and more direct pathways, which can improve airflow and throttle response.

Cons of Carbon Fiber Intake Systems

1. High Cost

Carbon fiber is an expensive material to produce and work with. As a result, carbon fiber intake systems are typically much more expensive than their plastic or aluminum counterparts. This can be a major drawback for budget-conscious tuners.

2. Durability Concerns

While carbon fiber is strong, it can be brittle under certain conditions. Poor-quality manufacturing or prolonged exposure to extreme temperatures may lead to cracking or delamination over time.

3. Marginal Gains

For many vehicles, especially naturally aspirated engines, the performance gains from a carbon fiber intake may be minimal without additional supporting modifications (like ECU tuning or exhaust upgrades). Some users may not notice a significant difference beyond the looks and sound.

4. Installation Complexity

Some carbon fiber intake systems are designed as direct replacements, while others may require modifications or special tools to install. Improper installation can lead to air leaks, poor engine performance, or check engine lights.

Conclusion

Carbon fiber intake systems can be a worthwhile upgrade for enthusiasts looking to combine performance and aesthetics. They offer tangible benefits in terms of airflow and heat management, along with a high-end appearance. However, their high cost and potential durability concerns mean they’re not the perfect solution for everyone. As with any modification, it's important to consider your goals, budget, and vehicle setup before investing.

Whether you're building a show car, a daily driver, or a track monster, make sure to choose a reputable brand and consult professionals when necessary.

Let me know if you’d like a version translated into Chinese or formatted for a website like Medium or WordPress!