In the automotive industry, precision and quality are crucial when it comes to manufacturing components. One method that has revolutionized the production of automotive parts is Computer Numerical Control (CNC machining. This cutting technology not only ensures precise and accurate manufacturing but also enables the creation of custom-designed parts. This article will delve into the process of utilizing CNC machining to produce high-quality automotive components.

Design:

The first step in CNC machining is to create a detailed design of the desired automotive part using computer-aided design (CAD) software. This software allows engineers to design intricate shapes and precisely define specifications.

Material Selection:

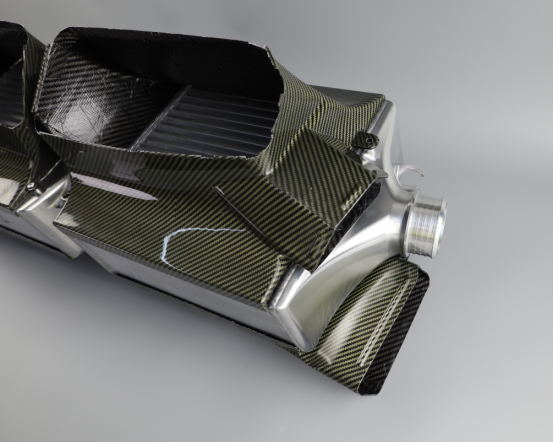

Selecting the appropriate material for the automotive part is vital to ensure strength, durability, and functionality. CNC machining works with a wide range of materials, including aluminum alloys, stainless steel, titanium, and plastics, allowing for versatile manufacturing options.

CNC Programming:

Once the design is finalized, the next step is to translate it into a CNC program. Skilled programmers use specialized software to generate the toolpaths and instructions necessary for the CNC machine to produce the desired part.

Machine Setup:

The CNC machine is then set up according to the specifications of the design and material. This includes securing the raw material in place and configuring the machine's cutting tools and parameters.

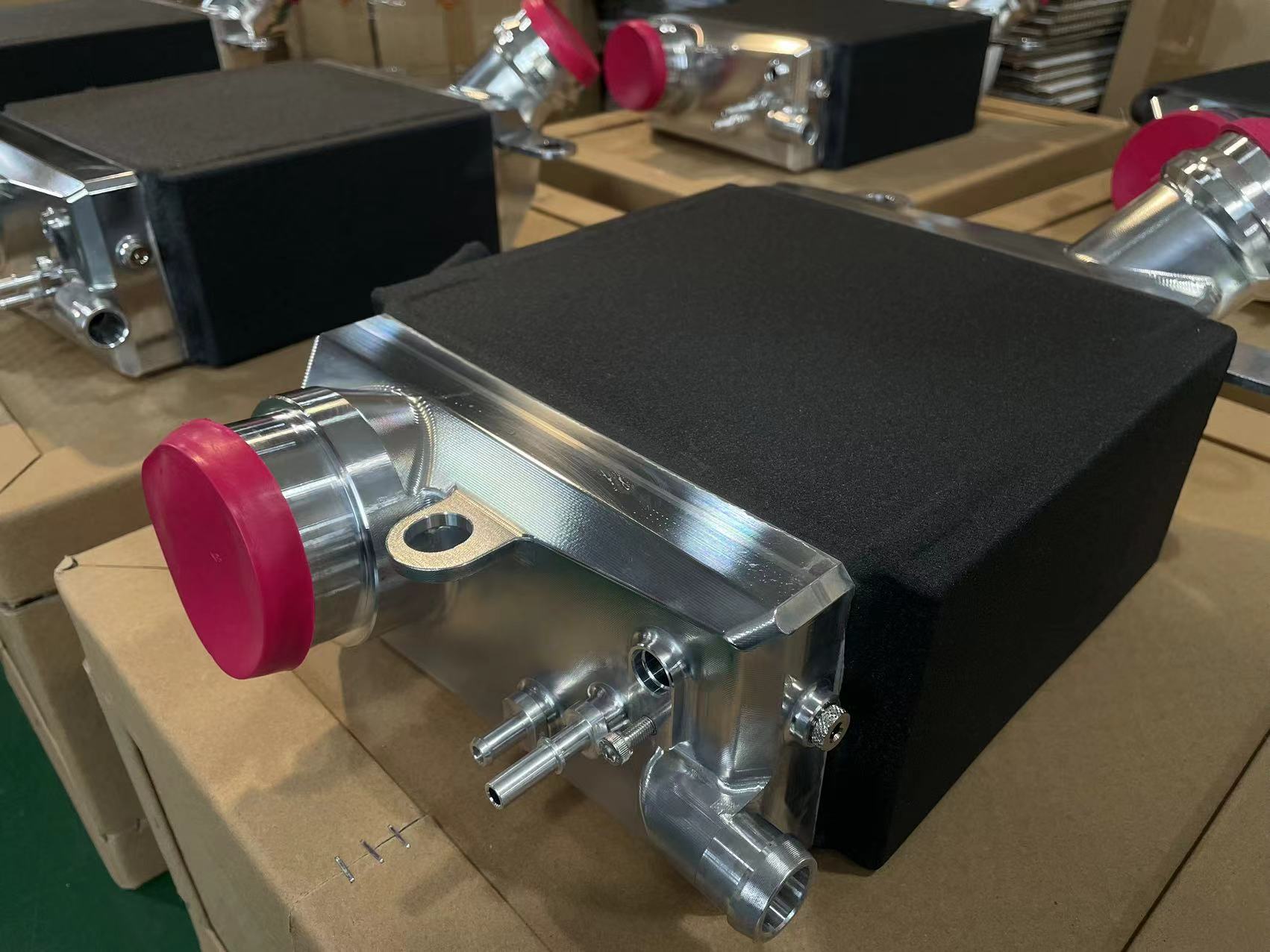

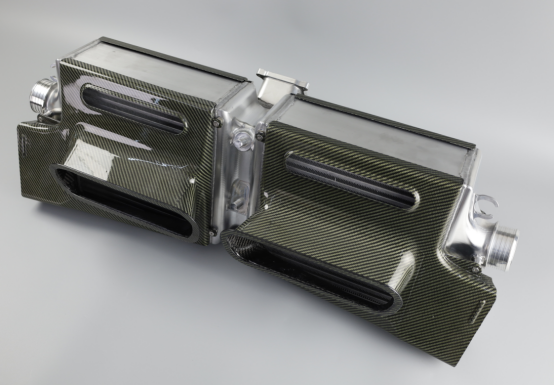

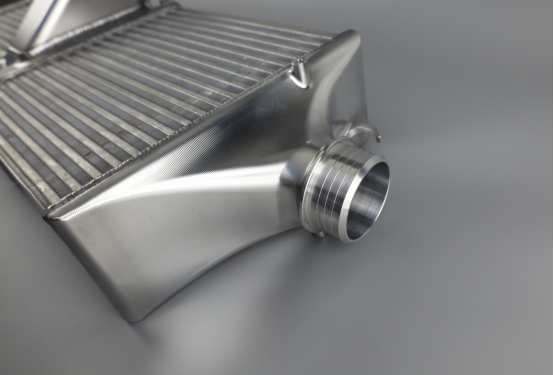

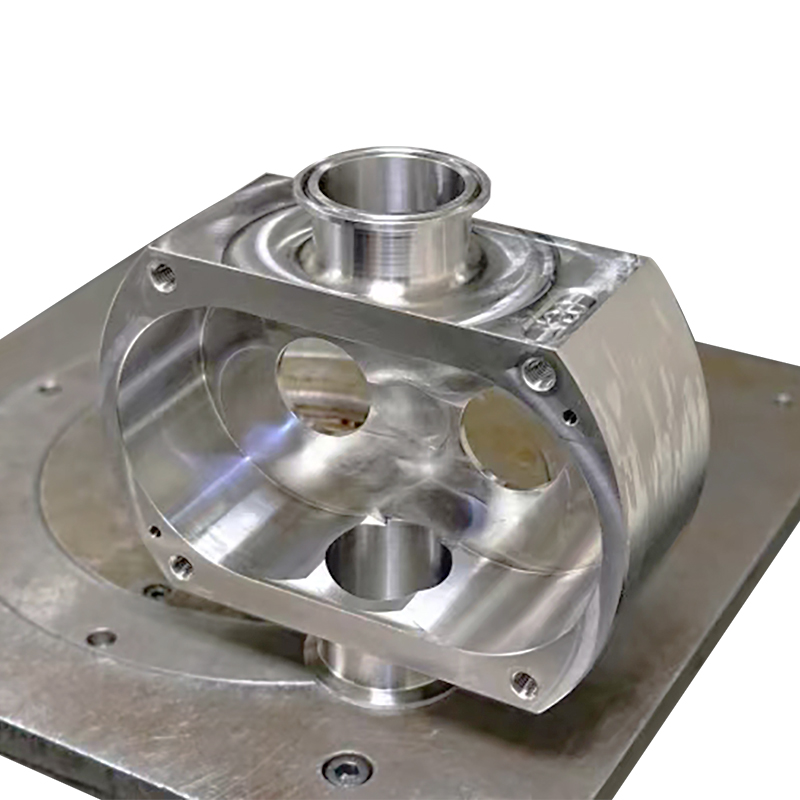

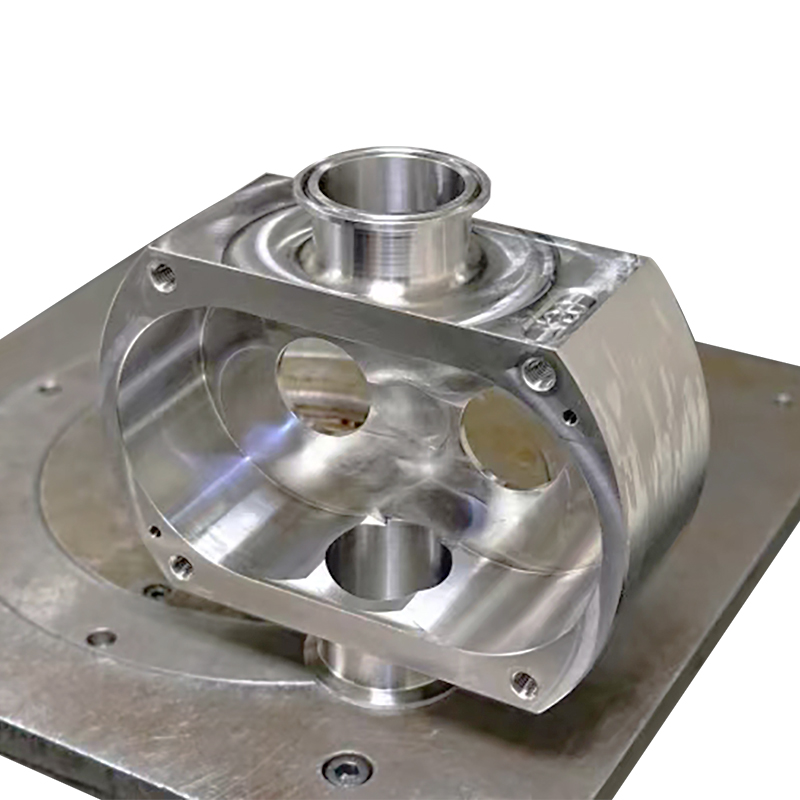

Machining Process:

With the CNC machine properly configured, the machining process begins. The machine precisely follows the programmed toolpaths, cutting away excess material and shaping the part with exceptional accuracy and consistency. The process may involve operations such as milling, drilling, turning, or grinding, depending on the complexity of the design.

Quality Control:

As the part is machined, quality control measures are implemented to ensure that it meets the required specifications. Advanced technologies like metrology systems and coordinate measuring machines (CMMs) are used for dimensional inspections to verify the accuracy of the produced parts.

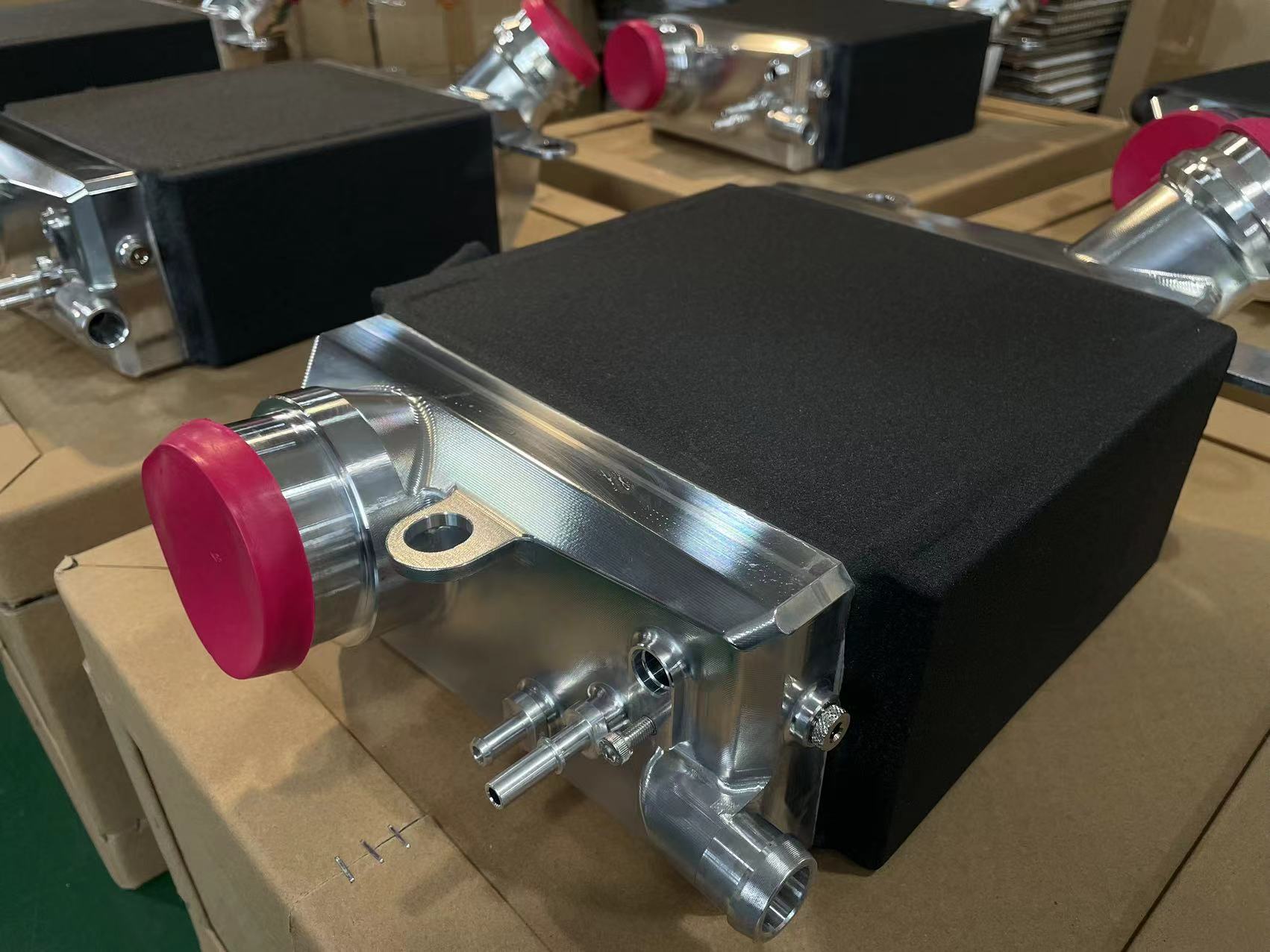

Finishing and Surface Treatment:

Depending on the requirements, additional finishing processes such as deburring, polishing, or coating may be applied to enhance the surface appearance and protect the part from corrosion or wear.

Testing and Evaluation:

The final step involves rigorous testing and evaluation of the machined automotive part to ensure its performance and reliability. This may include functionality tests, stress tests, or simulation analysis using advanced software.

Advantages of CNC Machining for Automotive Parts:

· Exceptional precision and accuracy

· Efficient manufacturing process

· Versatile material options

· Customization and flexibility

· Consistency and repeatability

· Reduction in human error and increased productivity

CNC machining has revolutionized the manufacturing of automotive parts, offering precision, quality, and customization options that traditional methods cannot match. By leveraging cutting-edge technology and skilled programming, automotive component manufacturers can achieve exceptional results. Whether it's prototyping, producing small batches, or large-scale production, CNC machining proves to be a game-changer in the automotive industry, ensuring that your vehicles perform at their best.