- One series for multiple solutions, the King Long PEV6, PEV9, and PEV12 are designed to meet a wide range of passenger transport needs, all with the same commitment to efficiency and advanced safety.

PEV6: Compact and agile, perfect for short-distance shuttle services and urban connections.

PEV9: A mid-size solution balancing passenger capacity with extended driving range.

PEV12: Long-range capability for major routes and high-demand operations.

All models come standard with air suspension, EBS, delivering a smoother, safer, and smarter ride.

No matter the distance or demand, the PEV series moves you toward a cleaner, brighter future.

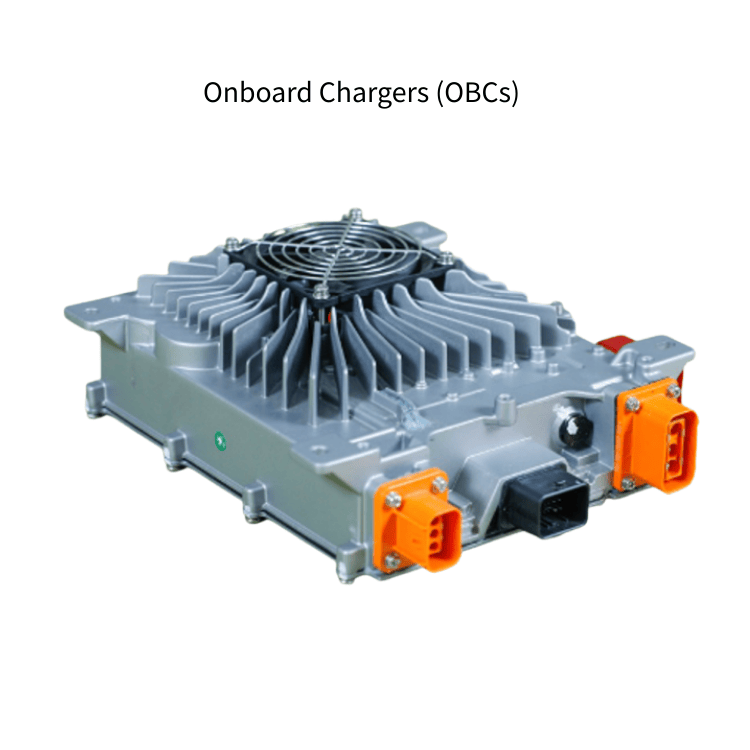

Common Problems with Onboard Chargers (OBCs) in Electric Vehicles and How Nanocrystalline Cores Solve Them

Introduction to Onboard Chargers (OBCs) and Their Role in Electric Vehicles

Onboard Chargers (OBCs) are a critical part of electric vehicles (EVs), converting AC electricity from the grid into the DC power needed to charge the vehicle's high-voltage battery. As EV demand grows, the need for faster and more efficient charging has increased, which brings new challenges to OBC designs. These challenges are primarily related to heat management and electromagnetic interference (EMI), both of which can severely impact the performance and lifespan of OBCs. This article discusses the common problems associated with OBCs and how nanocrystalline cores provide an effective solution.

The Key Problems in OBCs: Heat and Electromagnetic Interference

-

Overheating and Performance Degradation

A major concern for OBCs is heat, which results from the energy losses that occur during power conversion. Excessive heat can cause components to degrade faster and force the system to throttle its performance to avoid damage. This can reduce the overall efficiency of the vehicle's charging system and lead to increased failure rates in the power electronics. For instance, when operating at maximum capacity, OBCs can experience failure rates that are 40% higher than at normal operating levels, primarily due to overheating.

-

Electromagnetic Interference (EMI)

High-speed switching, a characteristic feature of OBCs, generates EMI. This interference can disrupt the vehicle's other sensitive electronic systems, such as communication buses and infotainment units, leading to potential malfunctions. Modern power semiconductors, like GaN (Gallium Nitride) and SiC (Silicon Carbide), operate at high frequencies, generating electromagnetic noise in the 2.4 GHz and 5 GHz bands, which requires highly efficient filtering solutions.

How Nanocrystalline Cores Solve the Heat and EMI Issues

-

Reducing Heat Generation: The Role of Nanocrystalline Cores

Nanocrystalline cores have an exceptional ability to reduce core losses, which are responsible for generating heat. Their grain structure, which is much smaller than conventional magnetic materials, results in significantly lower core losses, reducing heat generation by up to 1000 times compared to traditional materials. This reduction in heat allows OBCs to operate at higher power levels without the need for bulky cooling systems, which leads to a more compact and efficient design.

-

Suppressing Electromagnetic Interference (EMI)

Nanocrystalline cores excel in EMI suppression due to their high permeability. This allows them to absorb high-frequency noise over a broad range of frequencies, making them ideal for use in common-mode chokes (CMCs) designed to filter out EMI. By improving noise suppression, nanocrystalline cores ensure that the OBC can meet stringent EMC standards and maintain the integrity of the vehicle's electronic systems.

Nanocrystalline Cores vs. Traditional Ferrite Cores: A Comparative Analysis

| Parameter | Nanocrystalline Cores | Ferrite Cores |

|---|---|---|

| Saturation Flux (Bs) | 1.2T | 0.4T |

| Max Operating Frequency | ≥1 MHz | <200 kHz |

| Curie Temperature | ∼570°C | ∼120°C |

| DC Bias Performance | >80%@100 Oe | 20%@100 Oe |

| Size/Weight | 50% weight, 75% size reduction | No significant reduction |

| Cost | Lower system-level cost | Higher due to additional cooling components |

The Future of OBC Design with Nanocrystalline Cores

Nanocrystalline cores are poised to revolutionize the design of onboard chargers for electric vehicles. By addressing the critical challenges of overheating and EMI, they enable the development of more efficient, compact, and reliable OBCs. This innovation is key to advancing EV technology and supporting the growing demand for faster, more efficient charging solutions.

How to check whether the clutch master cylinder is intact?

How to check whether the clutch master cylinder is intact?

Clutch Master Cylinder Basics

The clutch master cylinder is the pressure source in the hydraulic clutch system. Pressing the clutch pedal generates hydraulic pressure, driving the slave cylinder, and ultimately disengaging and engaging the clutch. It consists of components such as the piston, push rod, and inlet valve. Its normal service life is approximately two years or 60,000 kilometers, but its actual lifespan will be affected by driving habits and maintenance. When sourcing replacement parts, many car owners prefer a good price clutch master cylinder that still ensures quality and durability.

Clutch Master Cylinder Self-Inspection Methods

1. Basic Appearance Inspection

Seal Inspection:

Inspect the connections between the master and slave cylinders and the oil pipe connections for oil stains or leaks. Focus on the area around the piston push rod for moisture (this is a common leak location).

Check under the pedal for oil drips (if found, immediately inspect).

Fluid Condition Inspection:

Open the reservoir and check the brake fluid (DOT3/DOT4). Normally, the fluid should be clear and transparent. If it appears dark, turbid, or contains impurities, it needs to be replaced.

Check that the fluid level is within the standard range.

2. Functional Test

Pedal Stroke Test:

Measure the free travel of the clutch pedal (normal value is 10–15mm). Excessive or insufficient travel may indicate a master cylinder failure. Test the pedal for smooth return and any sticking.

Pressure Test:

Continuously depress the pedal and maintain pressure to observe whether the oil pressure steadily decreases.

Professional Test: Maintain pressure at 20–25 MPa for 30 minutes; leakage should be ≤ 0.5 mL/min.

Simple Method: Press and hold the pedal to feel for a gradual decrease in pressure.

Gear Shift Test:

Depress the clutch pedal and attempt to shift gears. If shifting gears is difficult or impossible, it may indicate a master cylinder failure. Be careful to distinguish between incomplete clutch disengagement and a transmission problem.

Common Symptoms and Cause Analysis

Based on actual vehicle owner cases and repair experience, clutch master cylinder failure often manifests in the following ways:

Symptom: Pedal does not return or returns slowly

Possible Cause: Master cylinder piston is stuck, return spring is defective

Solution: Clean or replace the master cylinder

Symptom: Pedal feels soft and lacks resistance

Possible Cause: Insufficient oil, air in the system, damaged seals

Solution: Add oil, bleed air, or replace seals

Symptom: Difficulty shifting gears

Possible Cause: Excessive master cylinder pushrod clearance, insufficient oil pressure

Solution: Adjust pushrod clearance or replace the master cylinder

Symptom: Oil leakage

Possible Cause: Deteriorated seals, cracked pump body

Solution: Replace seals or master cylinder assembly

Symptom: Pedal becomes heavier the more you press it

Possible Cause: Overadjustment of the master cylinder pushrod causes the check valve to close

Solution: Readjust the pushrod clearance

When Should the Master Cylinder Be Replaced?

It’s recommended to replace the clutch master cylinder directly if the following conditions occur:

Cracks or severe corrosion appear on the pump body

Significant wear on the piston cavity

The problem persists after multiple repairs

The mileage is approaching or exceeding the recommended replacement interval

When replacing, choose parts from a trusted clutch master cylinder factory or a reliable clutch master cylinder China supplier to ensure compatibility and long-lasting performance.

Safety Tip: If an inspection reveals severe oil leakage or complete failure in the clutch system, stop driving immediately and contact a qualified repair technician, as this may affect the operation of the brake system and pose a serious safety hazard.

Is replacing the clutch slave cylinder a big project?

1. Hydraulic slave cylinder: structure determines the complexity of maintenance

From the installation position, the hydraulic slave cylinder is usually close to the gearbox housing and surrounded by the engine, drive shaft and other components. When disassembling, the air filter, battery and even some pipelines must be removed first. The step of "disassembling peripheral components" alone takes 1-2 hours. More importantly, the slave cylinder and the master cylinder are connected by a high-pressure oil pipe, and the "air exhaust" operation must be performed after replacement. If the air is not exhausted, the clutch pedal stroke will become shorter and the gear shifting will fail. This step requires extremely high technical proficiency, and novices can easily rework repeatedly.

2. Differences in vehicle models: Taking Toyota clutch slave cylinder as an example to see the impact of design

Even if it is the same replacement of the slave cylinder, the construction difficulty of different models may be very different. Taking Toyota's clutch slave cylinder as an example, its design features directly affect the cost and time of maintenance.

The clutch slave cylinder of some Toyota models (such as Corolla and Lelink) is highly integrated with the gearbox, and the gearbox needs to be lifted to be disassembled. The lifting step alone requires a special bracket and 3-4 people to cooperate, and this alone will increase the working hours by 2-3 hours.

In addition, the interface design of Toyota's original slave cylinder is relatively special, and special tools must be matched when replacing it. If the repair shop does not have complete tools, it may be embarrassing to "take it down but not install it". This is why the repair quotes for the same clutch cylinder can differ by more than $100 on different models - the model design directly determines the "size of the project".

3. Parts selection: How to choose original parts & OEM clutch cylinder parts?

When replacing the clutch cylinder, the selection of parts is an unavoidable topic. There are currently two main types of products on the market: original parts and aftermarket parts. The difference between the two directly affects the repair effect and subsequent use costs.

The original clutch cylinder usually refers to officially authorized parts that are directly in line with the factory standards of the car. The quality is stable, but the price is higher. This type of part is suitable for car owners who have high requirements for reliability, especially for vehicles within the warranty period, to avoid problems with the parts affecting the warranty of the entire vehicle.

OEM clutch slave cylinder are "aftermarket parts" produced by manufacturers for OEMs. They are manufactured according to original factory standards, but are labeled with third-party brands, and the price is only 60%-70% of the original parts. At this point, I have to recommend a Chinese clutch cylinder manufacturer—KOMP, a brake cylinder and clutch cylinder manufacturer in Wuhu, China, with 24 years of professional manufacturing experience, good product quality, 1-year or 30,000KM warranty, and very favorable prices, which is the choice of many parts importers.

4. Summary: Is it a big project? Look at these 3 standards

A. Vehicle design: If the gearbox needs to be lifted (such as some Toyota models), it is a "big project"; if only the peripheral parts can be removed for replacement, it is a medium project.

B. Maintenance team: For professional stores, hydraulic cylinder replacement is a routine operation; if the repair shop lacks experience, it may become a time-consuming and labor-intensive "troublesome matter".

C. Accessories matching: Choosing original parts or aftermarket parts, and coordinating with standardized construction, can reduce the probability of rework, otherwise it may turn a small repair into a "protracted war".

What are the initial signs of clutch slave cylinder failure?

As the core component of the hydraulic clutch system, the health of the clutch slave cylinder directly affects driving safety and maintenance costs. According to statistics, 90% of clutch system failures are accompanied by abnormal slave cylinders, and early detection can save more than 60% of maintenance costs. This article will analyze seven key warning signs in detail to help you prevent problems before they happen.

Abnormal pedal feedback: the most intuitive warning

1. Soft and weak pedal

When you step on the clutch pedal, it feels like stepping on cotton, the stroke becomes significantly longer and the rebound is weak, which is often a typical manifestation of hydraulic oil leakage in the slave cylinder. Test method: Keep pressure after stepping on it quickly 3 times in a row. If the pedal sinks slowly, it is confirmed that there is a leak. Whether using a traditional or internal slave cylinder, any leakage in the system can lead to this soft pedal issue.

2. Pedal jamming

Metal friction sound accompanied by poor pedal movement may be caused by aging of the slave cylinder piston seal. It is recommended to check whether the slave cylinder dust cover is damaged. Impurities entering the interior will accelerate the wear of the seal. Reputable clutch slave cylinder manufacturers often emphasize the importance of seal integrity and dust protection in product design.

Difficult shifting: Deterioration of driving experience

3. Disappearance of gear suction

When the clutch is normally disengaged, it should be easy to shift into any gear. If there is an increase in gear shifting resistance or even a sound of gear clicking, it means that the slave cylinder may not be able to generate enough hydraulic pressure, resulting in incomplete clutch plate separation.

4. Low-speed gear is particularly difficult

This phenomenon is particularly obvious when starting a cold car. Wear inside the slave cylinder will cause pressure to change with temperature, and it is most sensitive when the vehicle is started for the first time in the morning.

Abnormal sound: an audio signal that cannot be ignored

5. High-frequency hissing sound

The sound of air leakage when lightly pressing the pedal in a quiet environment is often a sign of poor sealing of the slave cylinder push rod. This sound is easier to catch when the engine hood is open.

6. Metal knocking sound

Loosening of the slave cylinder fixing bolts will cause resonance and abnormal noise during operation. This type of sound is most obvious at the moment of clutch engagement, and it often occurs in old models over 5 years old.

Visible leakage: the most direct evidence

7. The appearance of hydraulic oil stains

Regularly check the surface of the slave cylinder and the connecting pipes:

Oil sludge accumulates on the black rubber dust cover

Metal pipe joints appear wet and reflective

Oil droplets remain under the pedal bracket

Emergency treatment and prevention suggestions

When any of the above symptoms are found:

Immediately check the clutch oil tank level (mostly located next to the brake oil tank)

Avoid long-term semi-clutch driving

Regularly clean the dust on the surface of the slave cylinder every month

It is recommended to replace the hydraulic oil every 60,000 kilometers

To ensure better reliability and durability, it is recommended to source replacement parts from a trusted China supplier clutch slave cylinder provider. For example, KOMP brand clutch slave cylinders. KOMP has 24 years of experience in brake cylinder and clutch cylinder production, provides a 1-year or 30,000KM warranty, and has high product quality. It is the choice of many auto repair shops. Additionally, perform a pressure test nearby when the symptoms first appear. Most repair shops provide free preliminary inspection services.

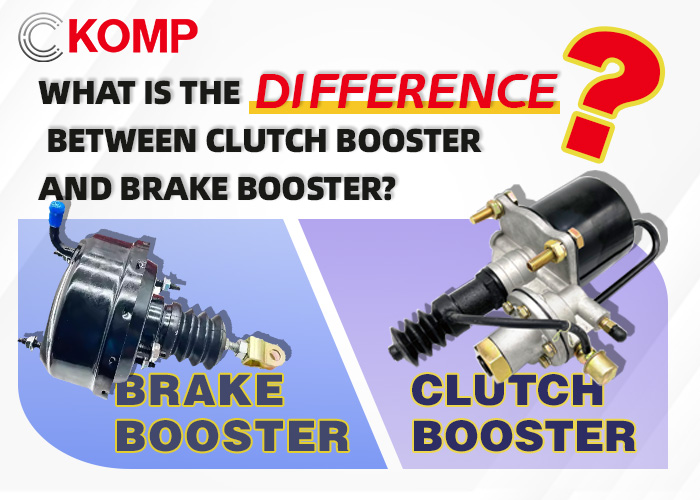

What is the difference between clutch booster and brake booster?

1. Function positioning difference

The clutch booster is designed for manual transmission. Its core functions are:

Amplify the pedal force by 5–8 times (the boost ratio of ordinary cars is about 1:6.5)

Help to completely separate the friction plate (stroke control accuracy ±0.5mm)

Achieve fast return (reset time ≤0.3 seconds)

For example, the clutch booster Isuzu systems are engineered specifically to meet the operational demands of heavy-duty vehicles, offering consistent performance in high-load environments.

The brake booster serves the braking system:

The typical boost ratio is more than 1:10 (SUV models can reach 1:12)

It is necessary to establish continuous hydraulic pressure (working pressure is usually 2–4 MPa)

Equipped with emergency brake assist function (pressure rises suddenly when EBA system intervenes)

2. Comparison of structural principles

Structural features of clutch booster:

Using diaphragm air chamber (diameter 80–120mm)

Hydraulic piston diameter is usually 18–25mm

Integrated accumulator (pre-stored pressure 0.4–0.6MPa)

Typical structure includes:

Control valve body

Hydraulic cylinder

Air pressure chamber

Push rod mechanism

China has become a major source for these products. A clutch booster factory in China typically specializes in large-scale production with strict quality control, making it a competitive supplier in the global aftermarket.

Brake booster core components:

Vacuum chamber (diameter 200–300mm)

Dual diaphragm design (standard for modern models)

Electronic vacuum pump (essential for new energy vehicles)

Key subsystems:

Vacuum check valve

Input push rod group

Reaction plate mechanism

Hydraulic master cylinder interface

Leading brake booster manufacturers focus on performance, safety certification, and electronic integration to meet the rising demand in both traditional and EV platforms.

3. Differences in working characteristics

Parameters

Clutch Booster

Brake Booster

Working pressure

0.8–1.2MPa

2–4MPa

Response time

50–80ms

30–50ms

Stroke

120–150mm

40–60mm

Temperature range

-30℃~120℃

-40℃~150℃

4. Comparison of fault modes

Common faults of clutch booster:

Hydraulic oil pressure leakage (aging of sealing ring)

Assist failure (insufficient accumulator pressure)

Slow pedal return (return spring fatigue)

Typical faults of brake booster:

Vacuum leakage (damaged diaphragm)

Uneven assist (worn reaction plate)

Hard pedal (blocked check valve)

5. Maintenance points

Clutch booster maintenance:

Check hydraulic oil every 30,000 kilometers

Exhaust air regularly (recommended every 2 years)

Pay attention to pedal free travel (standard 10–15mm)

Brake booster maintenance:

Annual inspection of vacuum line

Keep engine compartment clean

Pay attention to brake fluid replacement cycle (2 years/40,000 kilometers)

Wuhu compass autoparts technology Co., Ltd is a clutch booster and brake booster manufacturer in China, KOMP is its brand name, KOMP can provide factory price clutch booster and brake booster, and provide one year or 30000KM warranty, if you want to buy good quality and affordable products, KOMP is your good choice!

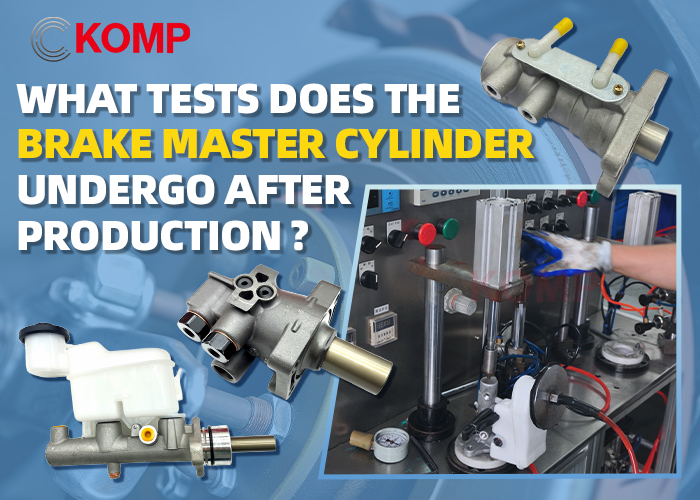

What Tests Does the Brake Master Cylinder Undergo After Production?

The brake master cylinder is one of the most critical safety components in any vehicle. Whether it’s for a mass-produced sedan or a performance vehicle, after production, the factory will undergo Air Tightness (Leakage) Test and Hydraulic Pressure Test. For some cylinder wholesalers, the products also need to undergo Functional Stroke Test and Endurance Test.

1. Air Tightness (Leakage) Test

The first test checks for internal and external leakage. The master cylinder is sealed and subjected to air pressure to simulate real operating conditions. Any pressure drop indicates a leak. This test is crucial for both custom brake master cylinder units used in modified vehicles and standard models to ensure no brake fluid or air escapes during use.

2. Hydraulic Pressure Test

Next, the cylinder undergoes a hydraulic pressure test to verify its ability to generate and maintain pressure under load. The cylinder is filled with brake fluid and pressurized. Engineers monitor the system to confirm that it can consistently maintain pressure without any loss. For an OEM brake master cylinder, this ensures it meets factory specifications and can safely integrate with the original braking system.

3. Functional Stroke Test

This test measures the stroke length of the piston inside the master cylinder. The stroke must fall within a specified range to ensure the brakes engage properly. If the stroke is too short or too long, it may indicate a manufacturing defect. This is particularly important for models such as the brake master cylinder Ford Ranger, which must meet strict performance requirements under varying load conditions.

4. Endurance Test

To simulate long-term use, some cylinders undergo endurance testing. The cylinder is cycled thousands of times under pressure to mimic years of braking activity. This helps identify early wear or failure points that wouldn’t appear in short-term testing.

For example, the Chinese brand KOMP comes from Wuhu Campass Autoparts Technology Co., Ltd. It is a high-quality brake master cylinder factory. Their products are inspected and tested for quality before being sold to customers to ensure that each product is usable. At the same time, KOMP provides a 1-year or 30,000 km warranty, which is the choice of many brake pump wholesalers.

Every brake master cylinder must undergo a rigorous series of tests to guarantee performance, safety, and reliability. Whether you're installing a custom brake master cylinder for enhanced performance, replacing an OEM brake master cylinder for factory-fit assurance, or ensuring the durability of a brake master cylinder Ford Ranger, these post-production tests are essential for road safety and customer trust.

Which Factory in China Produces Brake Wheel Cylinders?

When it comes to sourcing high-quality brake wheel cylinders from China, one name stands out in the industry — KOMP, the brand of Wuhu Campass Autoparts Technology Co., Ltd. Located in one of China’s key automotive parts manufacturing regions, KOMP has built a strong reputation for producing reliable, precision-engineered brake components for both domestic and international markets.

KOMP specializes in a wide range of autoparts including brake wheel cylinders, brake master cylinders, clutch master cylinders, and clutch slave cylinders. Its expertise and advanced production facilities enable the company to meet diverse customer needs, from large-scale Wholesale brake wheel cylinder orders to specialized designs for specific vehicle models.

KOMP was founded in 2001 and has 24 years of professional experience in cylinder production. The company has more than 9,000 models of brake and clutch cylinders. No matter which OEM number of brake cylinder you need, it can produce it for you. The company has 16,000 square meters and 50 production lines. We provide fast delivery and low minimum order quantity, factory price, and have a professional service team to better serve you.

The raw materials used by KOMP brake wheel cylinder China supplier are all imported from Japan, such as EP35 rubber, ZL111 aluminum and high-quality cast iron. The product has high quality and long service life. The product can withstand the temperature test of -40℃ to 180℃. precisely machined to prevent fluid leaks, and rigorously tested to meet strict quality standards.

Regarding customization, KOMP can design logos and color box drawings for customers free of charge; it can also laser engrave products for customers free of charge, and can provide customers with better customization services.

Quality assurance is a top priority at KOMP. Every brake cylinder undergoes thorough inspection and performance testing before shipment. The company backs its products with a one-year or 30,000 km warranty, giving customers confidence in both durability and after-sales support. This commitment to reliability and service has helped KOMP maintain strong, long-term relationships with clients around the world.

For buyers seeking a trusted Chinese factory brake wheel cylinder, KOMP offers a winning combination of manufacturing expertise, customization capability, and quality assurance. Whether you need bulk orders for wholesale distribution or specialized designs for niche applications, Wuhu Campass Autoparts Technology Co., Ltd. delivers dependable solutions that keep vehicles safe and customers satisfied.

Air compressor filters - choose Coolworks

- Coolworks specializes in manufacturing air compressor oil filters, oil-gas separators and air filters

——these high-quality filters can ensure the stable operation of your equipment.

.

- Reasons to choose Coolworks filters:

✅Factory direct supply, price advantage (no middlemen taking a cut)

✅Over 4,000 models available, compatible with mainstream brands such as Atlas Copco and Ingersoll Rand

✅Comprehensive pre-sale and after-sale services (professional team dedicated to serving you)

.

- ✨If you need high cost-performance filters,

please feel free to contact us at any time.

How to choose the right filter?

Coolworks Warm reminder:

- When purchasing #filters, quality is very important.

- Also take into account the affordability of the product.

- When choosing a filter that matches your needs,

- Finding the balance between high quality and reasonable price is crucial.

-

Coolworks filters are known for their high quality and cost performance,

And become a reliable choice for many customers.

-

In addition,

Our lower pricing is also appreciated by those looking to save money,

Customer support without sacrificing performance.

-

Select Coolworks filter,

We won't let you down.